Bosch Research

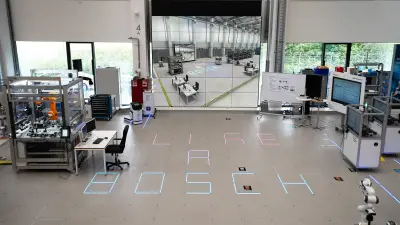

At Bosch Research, research meets application. Around 1,800 experts around the world develop the technologies of tomorrow — and beyond.

The world in which we live is changing rapidly. Global megatrends such as climate change and digitalization influence virtually every area of day-to-day life. One thing that doesn’t change is Bosch’s mission to create technology that is “Invented for life” — in other words using technological innovations to improve people’s quality of life and using natural resources responsibly.

Bosch Research sees itself as the spearhead of innovation at Bosch: Our researchers are involved in around a quarter of the patent applications filed by Bosch. On the one hand, we help all Bosch divisions to develop the next generation of products or the generation after that. On the other hand, we look far into the future: with our partners in science and industry, we identify technologies and trends which will shape our lives in the future and make them usable for the entire company. As a global team with around 1,800 experts from all over the world, we cover a wide range of areas with our research. Whether it be automation, digitalization and connectivity, artificial intelligence (AI), electrification, climate action and sustainability or healthcare: Bosch Research combines top-level research with specific technological developments.

Research fields

At Bosch Research, we actively shape the future by researching and developing sustainable technologies that improve people’s lives and make the economy more efficient. Our 1,800 researchers bridge the gap between science and industry and explore technologies and trends in the fields of automation, digitalization and connectivity, artificial intelligence, electrification, climate action and sustainability, and healthcare.

Contact

Get in touch with us to learn more about our cutting-edge research and collaboration opportunities.

Contact special interest media

Dora Constantinita

Senior Manager Corporate Communications, Bosch Research

+49(711)811-8791

dora.constantinita@de.bosch.com

Contact Human Resources

Sarah Schneck

Human Resources Business Partner, Bosch Research

+49(9352)18-8527

Sarah.Schneck@de.bosch.com