The pioneering years of fuel cell technology

The long road to a breakthrough

It won’t be too long before hydrogen-powered fuel cells become a part of our everyday lives. There are a number of promising approaches on the horizon, but green hydrogen isn’t yet available in the volumes required for the widespread, sustainable use of fuel cell technology. Bosch became involved at an early stage and develops technologies for generating, compressing, storing and utilizing hydrogen. A look back at the past century shows how Bosch played a pioneering role in fuel cell technology’s long development journey.

An old but recurring topic

As early as 1894, Wilhelm Ostwald, the first chair of physical chemistry at Leipzig University, predicted that, in the future, electricity would be generated through electrochemical conversion, namely by burning hydrogen and oxygen and producing water as a byproduct, rather than using conventional combustion techniques.

In other words, the history of fuel cells can be traced back almost 130 years. If you include the research of British physicist William Robert Grove, the development of fuel cell technology started as far back as 1839. Grove discovered during the electrolysis of water to hydrogen and oxygen that this process could also be operated in reverse.

A new energy source?

In June 1964, Werner Herrmann, then head of the laboratory for electrochemical power supplies at Bosch, wrote the company’s first scientific paper on the subject of fuel cells. Herrmann found that burning hydrogen and oxygen to create heat was a process with a level of efficiency of approximately 30 percent. This contrasted with an efficiency of 85 percent achieved by the chemical reaction of hydrogen and oxygen atoms between two electrodes submerged in electrolytic liquid. These were promising findings.

For space exploration rather than the road

Herrmann envisaged realistic possibilities for generating electricity, including in space travel, and firmly believed that the small number of applications that appeared achievable in his lifetime — such as short-range transportation vehicles — would rapidly pave the way for larger-scale use cases like road vehicles. Although not all of his predictions came true, at least one — space exploration — did: A fuel cell system designed by jet engine manufacturer Pratt & Whitney was used to generate electricity on the Apollo 11 mission to the moon.

It’s no coincidence that Herrmann was looking into the subject and that Bosch tested the first laboratory prototype of a fuel cell that same year. After all, converting energy has always been one of Bosch's core competencies, and the search for greater efficiency at lower energy consumption is an integral part of the company’s research agenda.

The fundamental issue in 1964 was turning the concept into a mass-market product that was both powerful and durable while also able to be manufactured on a wider scale and therefore at an affordable cost. This challenge would become a central theme of the pioneering years of fuel cell research — and remain relevant all the way through to the next millennium.

Mission: new insights

Wilhelm Ilge and two experts from Bosch research who accompanied him in May 1965 had a tight schedule. Ilge’s mission was to visit renowned scientific institutions in the United States to gain some insight into the progress being made in battery technology. Fuel cell technology was on his mind, too.

The fourth stop on the tour was the Battelle Institute in Columbus, Ohio, where a meeting was planned with six scientists to talk about the latest fuel cell technology and research. The research team had sent six questions in advance from Stuttgart to the United States, the main one being which electrode materials and which electrolytes were best suited to fuel cells. The insights would eventually form the subject of further research at Bosch. But they were just one piece of a puzzle that would remain one of the company’s experimental fields of research for a long time to come.

The first result

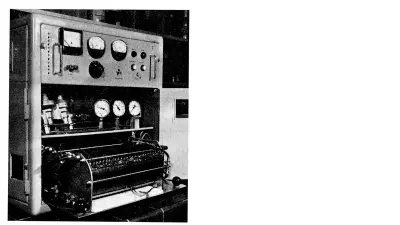

Bosch unveiled its first laboratory prototype of a fuel cell in March 1968. After years of preliminary work, it had been developed as an autonomous system with a nominal output of 100 watts.

By way of comparison, that’s about one one-thousandth of the power of Bosch’s current SOFC system, which is used to generate electricity and heat. But the project wasn’t about delivering significant amounts of power, it was about feasibility, fatigue testing, and meeting the fundamental requirements for mass production. This prototype was designed to generate energy through the reaction of methane, not hydrogen, with oxygen, to ensure that the process remained affordable. However, the drawback here was that carbon dioxide was also produced as a byproduct in addition to water, and the energy density of the natural gas used was far lower than that of hydrogen.

Promising future, but still some way to go

Around two years later, four Bosch researchers summarized their findings to date in an article for specialist publication Metalloberfläche, listing all of the pros and cons/advantages and disadvantages of various fuel types and materials to generate power through chemical reactions in fuel cells. When they came to the question of the financial viability of fuel cell technology, the four researchers were forced to conclude that this remained a major sticking point of the technology. Given the price of raw materials, the new technology was in no way economically competitive with conventional combustion methods used in homes, industry, or transportation. Environmental aspects like those discussed nowadays weren’t even considered back then.

The outlook

The development of fuel cell technology has a great deal in common with the history of battery-powered all-electric vehicles, which has also been plagued by numerous setbacks. Electric vehicles needed half a century before scientific advances made economic efficiency and the potential for commercial success a possibility. In the mobility industry, the mass production of fuel cell drive modules is just around the corner.

Author: Dietrich Kuhlgatz