Environmental protection along the value chain

We leverage the innovation potential of Bosch and our partners to protect the climate, save water, especially where it is scarce, and strengthen the circular economy.

Climate action

Climate change is one of the biggest challenges facing humanity: stopping it is a task for society as a whole.

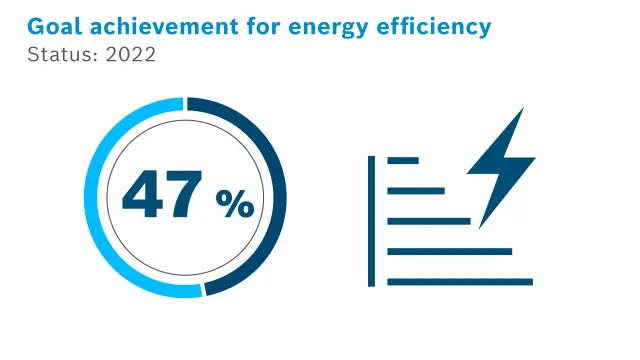

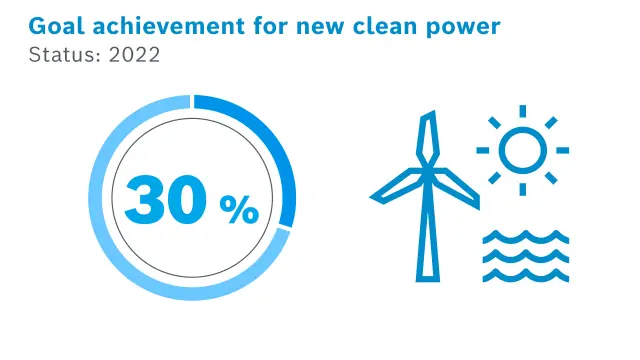

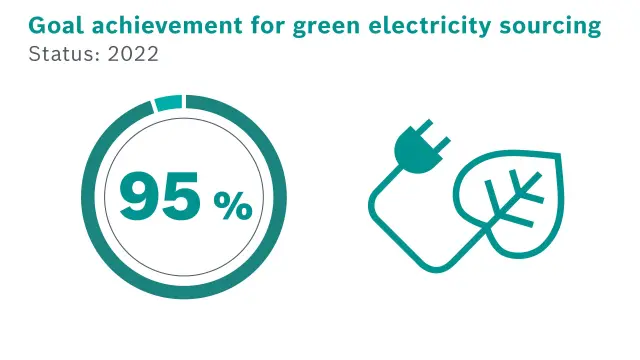

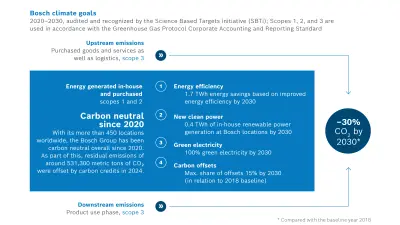

As early as 2020, the Bosch Group with its more than 450 locations worldwide has been carbon neutral overall (scope 1 & 2)*. Four levers were used to achieve carbon neutrality: increasing energy efficiency, generating our own energy from renewable sources (new clean power), purchasing electricity from renewable sources (green electricity), and — as the last resort — using carbon credits to offset residual CO₂ emissions. In 2024, residual emissions of around 531,300 metric tons of CO₂ were offset by carbon credits.

At the same time, we also want to reduce emissions produced outside Bosch’s direct sphere of influence (scope 3), for example at suppliers, in logistics, or when our products are used. Our aim is to reduce these upstream and downstream emissions by 30 percent in absolute terms by 2030, compared with the baseline year 2018 — irrespective of our company’s growth.

The Science Based Targets initiative (SBTi) endorsed our climate targets for the 1.5 degree pathway.** This means that Bosch has science-based climate targets for the entire value chain — from purchasing to the product use phase.

* Scopes 1, 2, and 3 are used here in accordance with the Greenhouse Gas Protocol Corporate Accounting and Reporting Standard. We have taken into account the effects of CO₂ and of other greenhouse gases, as well as climate-relevant substances, to the extent that these are of relevance for the analysis. To enable comparability between the climate impact of the various greenhouse gases and substances of relevance for the climate, emissions are presented in CO₂ equivalents. For ease of reading, we use the terms CO₂ and CO₂ equivalents synonymously.

** Robert Bosch GmbH’s entry in the SBTi’s target dashboard

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

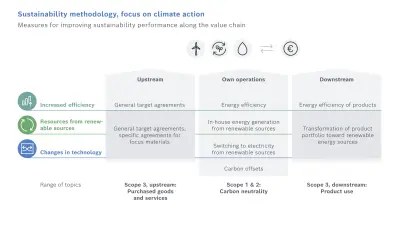

Climate action across the entire value chain

We want to shape climate action beyond our immediate sphere of influence (scopes 1 and 2) and, where possible, also systematically reduce upstream and downstream emissions (scope 3). We aim to cut these by 30 percent in absolute terms by 2030 compared with the baseline year 2018. In this process, we are focusing on the categories that make up around 98 percent of our scope 3 emissions: upstream emissions in the Bosch value chain primarily concern purchased goods and services as well as logistics. Downstream emissions are mainly caused by the use of our products.

Purchased goods and services

To reduce upstream CO₂ emissions in purchasing, we drew up a steering concept that includes two instruments:

- General target agreements with suppliers to reduce their CO₂ emissions, preferably in combination with a specific SBTi commitment.

- Specific agreements for focus materials such as steel, aluminum, copper, and plastics as these materials are responsible for a significant portion of CO₂ emissions in the supply chain. To purchase materials that are as low-carbon as possible in the future, we analyed the specific CO₂ reduction potential and identified reduction paths, as well as launched pilot projects in some divisions.

Logistics

In logistics, we aim above all to reduce CO₂ emitted during the transport of goods. We have a variety of instruments at our disposal here:

- Optimizing freight

- Using alternative drives and fuels

- Reducing air transport

- Improving packaging design

- Consistent use of the total cost of ownership (TCO) approach

Product use

Around 90 percent of scope 3 emissions are generated during the product life cycle, which is why energy efficiency in product development is a high priority for us. We currently see the greatest potential for lowering CO₂ emissions in those divisions in which products require a relevant amount of energy, that is above all mobility, thermotechnology, industrial drive and control technology, and household appliances. The focus is on three leverage points in each case:

- Boosting energy efficiency

- Market transformation and portfolio optimization

- Transformation of the energy sector through the use of green electricity, hydrogen, and biogas

Since 2018, we have cut our scope 3 emissions by around 33 percent, down to 308 million metric tons of CO₂ in 2024.

Encouraged by this success, we have decided to significantly increase our previous reduction target of 15 percent. Compared to the baseline year 2018, we now intend to cut our scope 3 emissions by 30 percent in absolute terms by 2030. The challenge we are still facing is to mitigate future emissions relating to the anticipated sales growth by 2030. This is because the new percentage target value for reducing emissions was also purposefully set independently of sales growth, which means that the absolute amount to be mitigated will increase steadily as the company grows in future. We can directly influence the goal achievement through more efficient products. On the other hand, there are also a large number of external factors that Bosch can only influence indirectly, such as suppliers’ success in reducing CO₂ emissions, the speed of transformation processes in the energy and mobility sector, or general economic development.

For further information on the scope 3 emissions of the Bosch Group, see our key figures tool.

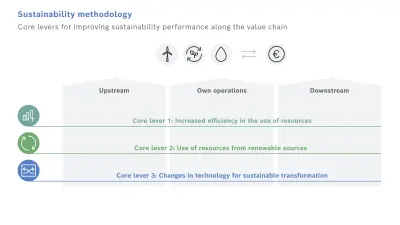

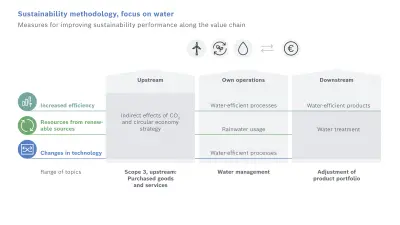

Uniform sustainability methodology enables systematic control

The environmental dimensions of our vision for sustainability are underpinned by the same logic. This is characterized by three core levers: increasing efficiency, purchasing resources from renewable sources, and changing the technology used. The three core levers can be applied to the entire value chain.

In this way, we create transparency with regard to the impact of the different measures, we show the relationships and interactions between the various influencing factors — and we thus provide the basis for in-depth scenarios in order to capture and control the effects of decisions in their entirety. This also reveals the additional differentiation potential of sustainability topics that will be of particular importance to Bosch in the future — as illustrated by trend and market analyses.

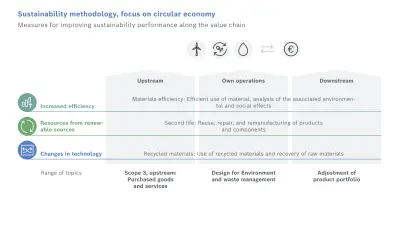

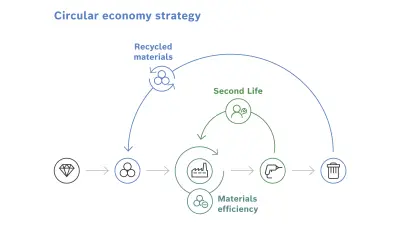

By consistently implementing the principle of the circular economy, it is possible to combine climate action, resource conservation and greater resilience for companies and their supply chains.

Circularity for a more sustainable product portfolio

With our circular economy strategy, we want to enhance the sustainability of our products over their entire life cycle – from procurement and production to use, return, and remanufacturing, right through to recycling and reuse of materials.

To this end, we endeavor to either create loops directly within Bosch or close them outside the company using established recycling processes. This way, we reduce the amount of materials used and our products’ carbon footprint*** and contribute toward achieving our scope 3 target. At the same time, we also avoid potential risks relating to compliance with environmental and social standards. Building a closed-loop system for materials has the particular advantage of eliminating parts of the value chain that are subject to risks, such as extraction of raw materials.

*** Unless otherwise stated, carbon footprint takes into account all greenhouse gas emissions ranging from raw material extraction to transport, production, sales, and use through to disposal of the product (cradle to grave) (see DIN EN ISO 14067).

Three levers of circularity

In our circular economy strategy we use a model comprising levers that can be applied across the entire value chain. Depending on the markets in which our divisions operate, however, the levers differ in their degree of effectiveness, are not equally applicable across the board, and therefore offer different development potential.

Materials efficiency

Improvements in materials utilization can reduce resource consumption and also cut the manufacturing cost of a product. Bosch can also directly influence the corresponding measures. For years, improvements in materials efficiency in production processes or products have therefore been an essential element of our product development process, where it is anchored in an internal standard via the Design for Environment (DfE) principle.

Second life

In the second lever, we have grouped together those measures that allow us to improve material flows or to close loops within the company. The concepts and activities of the divisions range from reusing products and their components to repairs and right through to remanufacturing — in each case with the objective of extending product and component life cycles.

Recycled materials

The third lever of our circular economy strategy — recycled materials — covers all measures to close the loop in the economy for materials such as steel, aluminum, and plastics. This way, we can reduce the use of primary materials, and lessen our environmental impact — as well as human rights risks from the extraction of raw materials. Our use of recycled materials also means that we are supporting the achievement of our scope 3 target.

We are focusing our efforts on areas where water is particularly scarce — and are using specific solutions to create the greatest possible benefit there.

Responsible use of water

Conscientious use of water is one of Bosch’s major priorities worldwide. Here, too, we have been pursuing a clear strategy for many years to counteract the scarcity of water.

We analyzed our company locations using the Water Risk Filter provided by the World Wide Fund for Nature (WWF). According to this analysis, 70 of our sites are located in areas of severe or severest water scarcity. We have set ourselves a target of reducing absolute water withdrawal at the 70 sites identified by 25 percent by 2025 compared with our 2017 baseline year — we achieved this target as early as 2023 and further reduced the withdrawal in 2024.

-28.5 percent

Bosch has reduced its water withdrawal at locations in water scarce regions by 28.5 percent compared to 2017.

Three starting points for conservative water use

Bosch needs water for cooling systems, sanitary facilities, and technical processes. We are focusing on process improvements, recycling, and the use of rainwater to further reduce water withdrawal at our company locations.

Improve processes so that less water is needed

Improve circulation to reuse the water consumed

Use rainwater instead of fresh water

In 2023, we were able to nearly double the quantity of rainwater used company-wide year on year to 140,000 m³.