Smart railroad giants

Smart, connected sensors made by Bosch make rail-freight operations more transparent and secure

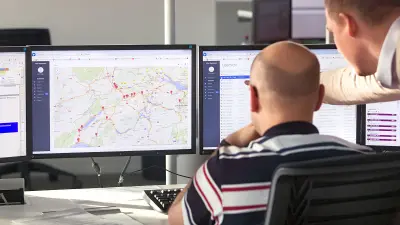

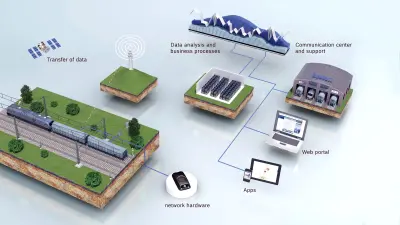

Bosch vehicle technology ensures that freight cars around the world move smoothly – not only on the tracks, but also on the internet. Monitoring wagons and their cargo creates transparency and results in more efficient logistics processes.

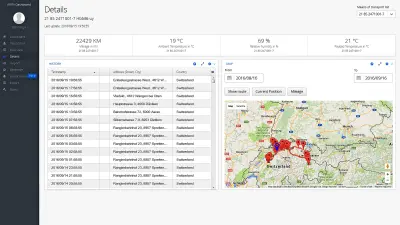

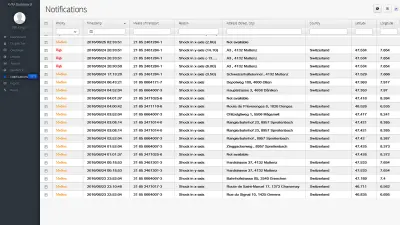

The refrigerated freight car 21 85 2471001-7 has covered a lot of ground: in just three months, it has traveled 21,543 kilometers over the length and breadth of Europe. It was exposed to an outside temperature of 38 degrees Celsius on August 26, and of minus 17 on November 13. On November 16, in Muttenz, Switzerland, it had to withstand a violent jolt during shunting. Dealing with such extremes is a fact of freight-car life. But what is new is that the car and its freight are monitored in the process, thanks to an alliance between Bosch Engineering and the Swiss rail freight company SBB Cargo.

How the technology works

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

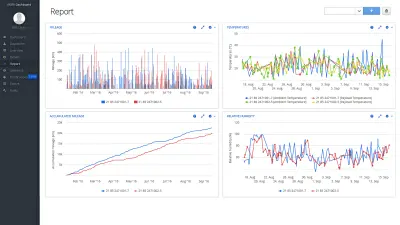

The refrigerated freight car 21 85 2471001-7 is one of roughly 150 smart freight cars plying Europe’s railroads for SBB Cargo. The plan is to retrofit as many as 1,500 additional cars. Their “smartness” comes from tried and tested technology and components that started out life in the Bosch automotive sector. “We use smart, connected sensors to gather data from freight cars and process them online,” says Bernhard Bihr, the president of Bosch Engineering. “The new system creates transparency along the logistics chain of rail, road, and sea transport, and contributes to more efficient management of the increased volume of freight transport.”

400 million

metric tons of freight are transported in Germany each year across a rail network covering nearly 40,000 kilometers

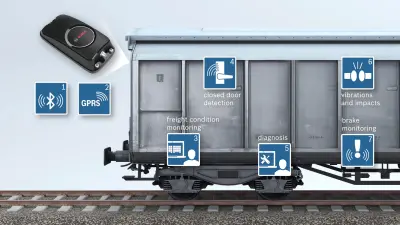

Known as AMRA (asset monitoring for railway applications), the monitoring system is a robust piece of hardware weighing just 700 grams, mass produced at Bosch for automotive applications. Embedded in or connected to this hardware, there are numerous sensors which measure things such as temperature and shocks. An integrated data transmitter connects the system with a cloud, where the data are analyzed, made available in a data portal, and integrated into the customer’s business processes. The system was developed as a retrofit solution for existing freight-car fleets, but can also be installed as original equipment during the manufacture of freight cars. An integrated battery with a service life of up to six years means it does not need an external power supply.

Summary

Bosch Engineering has developed a technology that uses smart, connected sensors to gather data from freight cars and process it online. Known as the AMRA system, the technology makes it easier monitor the condition of rail freight, and makes the transport process more secure.