Artificial intelligence meets domain knowledge

With their research into artificial intelligence, Bosch Research and the Bosch Center for Artificial Intelligence (BCAI) are laying the foundations for the products and services of the future. These will be even more efficient, safer and more user-friendly as a result.

Recognizing potential: Bosch focuses on connectivity and AI

Whether digital assistants or intelligent chatbots answer our questions, we receive automatically generated recommendations or our navigation device calculates the best route to our destination — artificial intelligence (AI) has become an established part of many people's everyday lives thanks to freely accessible applications. The availability of large quantities of data, enormous computing power and innovative algorithms have made this progress possible. AI is now able to solve complex problems and offer real-time decision-making recommendations.

In industry, artificial intelligence has played a central role for some time now. When used in the context of connected products where it has access to real-time data, it unleashes its full potential. Bosch recognized this potential long ago and established the Bosch Center for Artificial Intelligence (BCAI) back in 2017 to encourage not only the use of AI methods but also basic research into them. Bosch relies on AI in numerous product classes: since 2022, all electronic products allow connectivity and the data collected in the process are used to improve AI applications. All Bosch products and solutions now contain AI or have been developed or produced with the help of AI. With our research into artificial intelligence, Bosch Research and and BCAI are laying the foundations for this.

Intelligently connected: Collaboration between research and Bosch business divisions

At Bosch Research, connectivity and AI are now standard. We develop applications and solutions for all business areas across the group — from consumer goods and production systems to mobility and automated driving. AI methods play an elementary role here. AI research is pooled in Bosch Research's internal Center for Artificial Intelligence which assists the Group's divisions in developing and manufacturing products and solutions with the help of AI. Bosch Research and BCAI work together with the Bosch business divisions on specific applications during projects. As a result, futuristic AI research meets decades of domain expertise.

Getting to the bottom of things: BCAI develops new AI methods

With the research carried out by BCAI, Bosch Research is connecting physical products with the virtual world and making intelligent decisions possible through the use of AI. The AI-specific methods of BCAI are used in various sectors and applications here. The solutions from Bosch Research and BCAI result in user-friendly products as well as new business models which contribute to even more efficient manufacturing in the Factory of the Future. To this end, we bring together classic engineering and natural sciences with AI methods. BCAI focuses its research on the following AI methods.

AI methods

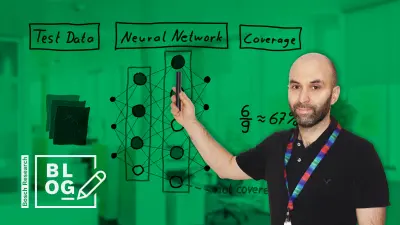

Deep learning involves machine learning systems that process data in neural networks at different levels. Machine “vision” as well as the speech comprehension and speech recognition of digital systems have their roots in deep learning. The method is used for solutions in automated driving, robotics or embedded AI systems.

Foundation models are the basis for the latest generation of AI models. They are trained on large data sets as well as on data sets of very different situations and modalities such as text, images or audio simultaneously. As a result, these models are able to solve a large number of new tasks with very high accuracy. We focus on adapting and using existing foundation models as well as on training our own models and implementing them on lower performance target hardware.

Natural language processing (NLP) is the focus of many recent research steps in AI, for example the text-based dialog systems “ChatGPT” and “Bard”. Our NLP methods focus on developing scalable solutions for Bosch's heterogeneous industrial context.

Generative AI describes models that are able to create new data points themselves, such as new images or texts. We work on generative models for synthetic data, designs of technical components or even the automated labeling of real data.

At the moment, deep learning and neural networks often struggle to incorporate structured domain knowledge and logical reasoning into predictions and results. With the neuro-symbolic AI method, domain knowledge becomes accessible by machine. It combines the flexible and data-driven power of deep Learning with so-called symbolic methods.

In order to understand and predict complex production process sequences as well as the movement habits of users and their interaction with Bosch products in the real world, we use the probabilistic modeling method — the statistical modeling of probabilities.

The reinforcement learning method goes beyond predictions. It plays a crucial role in controlling systems based on data, rather than simply anticipating how they will behave. Here, digital data are used to train the systems to make decisions and solve problems, both for sequential and non-sequential tasks.

Hybrid modeling combines fundamental models from statistics, physics or chemistry with data-driven models obtained from observations or simulations. These basic models are data-efficient, causally explainable and allow generalization. Conversely, data-driven approaches can describe complex and new processes for which no basic models are available. The integration of both methods in hybrid modeling makes it possible to optimize development steps and processes.

Intelligently applied: AI revolutionizes production and mobility

The experts at BCAI are thus carrying out basic research into AI on the very highest level. The futuristic methods are not only theoretical. Within the Bosch Group, the AI researchers are in constant contact with their colleagues from the business divisions. This interaction between research and development allows the new methods to be put directly into practice. Bosch Research implements pilot applications at the company’s production sites. The results help the researchers to develop methods for efficiently combining process knowledge and AI.

The AI Analytics Platform developed by BCAI is already in use in eight business divisions and at more than 1,500 production lines. It analyzes enormous quantities of data in order to identify quality problems and improve production on an ongoing basis. Along with other AI applications, the COLLIE (Collective Intelligence Excellence) project shows how domain knowledge and data can be combined intelligently. Through the use of a hybrid model, it was possible to develop and test a laser welding machine for the Bosch plant in Blaichach, Germany, much more quickly. For DeepInspect, the AI-based assembly assistant for the worker of tomorrow, we once again rely on a combination of classic domain knowledge and AI.

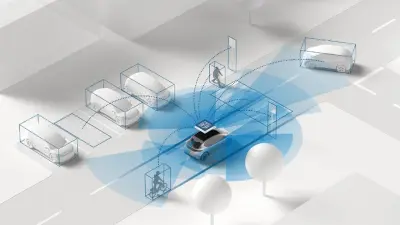

In mobility too, nothing is possible without AI nowadays. With the help of AI, vehicles can be turned into intelligent assistants. Assistance systems such as the multi purpose camera make automated driving safer and more reliable thanks to signal processing and AI-assisted behavioral prediction. When parking for example, an AI-assisted ultrasonic sensor will help with object recognition and will warn drivers of high, potentially dangerous objects. Collaborations beyond company boundaries are proof of our forward-looking research. These include the partnership with Cariad, the software subsidiary of the Volkswagen Group.

Summary

The research into artificial intelligence carried out by BCAI and Bosch Research is crucial as it allows Bosch's business units to further develop their products and thus stay one step ahead of the competition in many cases.