Innovation in the smallest of spaces

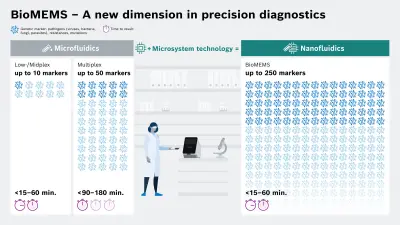

BioMEMS technology combines Bosch’s core competencies in MEMS, microfluidics and medical technology. This means that when pathogens are analyzed, more than 250 genetic traits can be identified directly at the point of care in less than 15 minutes in some cases.

Sepsis can be life-threatening if it is not treated quickly. In general, when it comes to identifying the causes of disease and pathogens, the faster the better. Relevant parameters are still predominantly analyzed in central laboratories, which can be time-consuming and also expensive. With the Vivalytic diagnostic platform, Bosch has already launched an analyzer on the market that guarantees fast and highly precise molecular diagnostics and can be used at the point of care — that is, directly on site in hospitals, medical practices or test centers. “Overall, the trend in healthcare is toward decentralized and personalized diagnostics that allow for rapid intervention and individual treatment,” says Jürgen Steigert, Head of Vivalytic Strategic Partnerships and New Technologies at Bosch Healthcare Solutions. “Tests will have to be carried out even faster, and even more pathogens identified in the future,” he says. This is now possible with BioMEMS technology, which expands the Vivalytic platform.

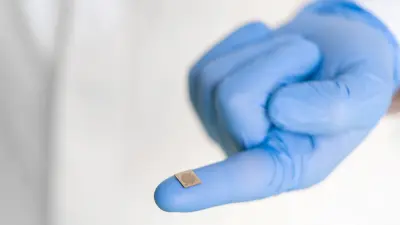

The BioMEMS chip in the Vivalytic cartridge enables completely new analysis methods with miniature diagnostics. A sample can be tested for up to 250 genetic targets simultaneously and automatically using parallel real-time PCR analyses — and all directly on site where the sample was taken. In some cases, the results can be available in less than 15 minutes.

Microfluidics and medical technology are combined with microsystem technology to achieve this. All three are core competencies of Bosch. Bosch is the world market leader in microelectromechanical systems (MEMS), with around four million chips produced every day. “The challenge was to combine the MEMS established at Bosch with medical technology in order to enable decentralized molecular diagnostic testing for a variety of pathogens,” explains Jochen Hoffmann, Chief Expert for Microfluidic Biological Systems at Bosch Research.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

This was the starting point for Daniel Podbiel’s PhD thesis, a research engineer at Bosch Research. A large team with different competencies was quickly put together. “The task was to develop a MEMS chip for microfluidic molecular diagnostics applications, i.e. to combine technology and biochemistry,” explains Daniel Podbiel.

Miniature diagnostics

For this purpose, it was necessary to adapt the chip surface’s wetting properties and give it a suitable microstructure, among other things. This ensures the necessary interaction with the fluids to be tested. “The BioMEMS chip allows us to implement completely new microfluidic functionalities in the nanoliter range,” says Daniel Podbiel. “This means that a pathogen is tested in a very, very small reaction vessel that is only about as thick as a human hair in diameter.” Compared to previous PCR reactions, this reduces the volumes of test fluids by a factor of 1,000 — in the nanoliter range.

Complex biochemistry must be able to take place on this small scale, because in microfluidic and nanofluidic systems the effects are different from those on a large scale, for example surface effects dominate over volume forces. This is relevant, for example, at the point in the process where the liquid must enter the chip’s cavities. These “little pots”, i.e. cavities, must be filled seamlessly, completely and without any gaps. “In addition, if genetic targets that are to be analyzed attach to the cavity walls, this can have a negative effect on the PCR reaction,” explains Jochen Hoffmann. “This requirement poses a particular challenge in miniaturization.”

Another aspect: BioMEMS technology aims to analyze as many genetic characteristics as possible, such as pathogens, germs, and bacteria. 250 analyzes can run in parallel on the BioMEMS chip. “We also had to find a solution to analyze 250 different types in these 250 little pots,” says Jochen Hoffmann, describing the challenge. For this, the respective analysis ingredient must be inserted into each cavity beforehand and it must be ensured that it remains there during the filling process and does not get into a cavity next to it. In this case, it would not be possible to unambiguously identify the pathogens.

“Developing the BioMEMS technology was only possible thanks to the strong and interdisciplinary team”, says Jürgen Steigert. It will be turned into a market-ready product in the Bosch divisions. But the following already applies everywhere now: When pathogens need to be identified as quickly as possible, as in the case of sepsis, BioMEMS technology can help save lives.