Invented quickly, sold cleverly

3D printers made by the Bosch subsidiary Dremel are becoming a common sight in U.S. classrooms

The Bosch subsidiary Dremel presented its first 3D printer after a very short development time. It was a great product, but consumer demand was not as high as hoped. A quick rethink led to the discovery of a new market with a great deal of potential: the scientists of tomorrow.

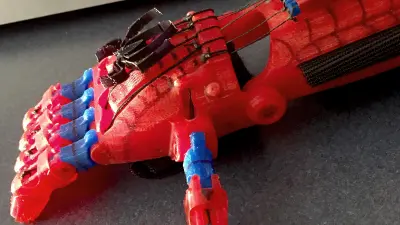

Young Eli can now choose whether to wear an arm with Spiderman designs on it or a more standard model. The fact that this youngster with a physical disability has a choice of functioning prosthetics comes down to a 3D printer. Sold under the Bosch Dremel brand, the printer is currently in use at Hardin-Jefferson High School in Sour Lake, Texas. “We started out using it to make name tags,” says Joy Schwartz, who teaches computer science and robotics at the school. “Next we created and printed Christmas decorations, then toys, and ultimately we learned how to produce movable arms.” But for Dremel, these examples are just the initial steps. In introducing 3D printing to schools, the Bosch subsidiary has set itself the challenging goal of nurturing the next generation of STEM (science, technology, engineering, mathematics) workers.

Teacher Joy Schwartz on using 3D printing at her school

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

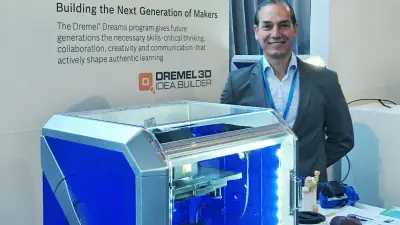

While the speed at which the school generated ideas for how to use 3D printing is impressive, the agility behind the product creation process is no less striking. In 2013, excited by the potential of this technology, a small team led by Gavin Jerome had the idea of developing the first device under the Bosch Dremel brand. By November 2014, the Idea Builder was ready. When it came to launching the product, one main point in its favor was its user-friendliness for non-professional customers. But it soon became clear that consumer demand was lower than hoped. “Faced with this fact, we had only two options,” Rafael Franca says. “Either call it a day and abandon the business – or find a new market.”

500 U.S. schools

are already working with Dremel 3D printers

A quick switch of responsibility – from the product development team to the business development team Franca leads – enabled Dremel to make the transition from the consumer market to the educational market. “Requirements have changed in training and education, particularly in the STEM fields,” Franca says. “STEM represents millions of jobs – a figure that is growing all the time. And yet there is clearly a shortage of young people coming through in these fields.” Dremel’s comprehensive approach, he says, can help the education system establish a new approach of its own.

40 percent

of U.S. schools are going to have their own 3D printers by 2018

The people at Dremel are still convinced that 3D printers will become an established consumer product in the future. “But right now we’re at the forefront of efforts to drive knowledge of STEM subjects from kindergarten to high school,” Franca says. “We want to inspire children as they develop their talent for intuitive learning, and we want to help students in their later STEM careers – whether with Bosch or elsewhere.” To this end, Dremel has worked with teachers to develop a special 3D teaching plan that aims to encourage tomorrow’s engineers to take risks, accept when they make mistakes, and persevere. Young Eli’s prosthetic arm is just one example of how to imbue 3D printing with relevance for people’s lives.

Summary

The Bosch subsidiary Dremel has developed a 3D printer which it sells primarily to schools. It is hoped that this technology will help inspire budding scientists.