From production line to data flow

a history of production

The newest recruit has to do the most unpleasant work. This harsh rule governed how jobs were allocated in Robert Bosch’s workshop in 1898. What was the most unpleasant work?

In the case of the company’s main product, the magneto ignition device, this was making the contact breakers, a job that required laborious filing. This prompted the new recruit Otto Grimmeisen to design a machine that would do this task for him.

Even at an early stage, therefore, there were clearly strong incentives for division of labor and mechanized production at Bosch.

Industrial revolution

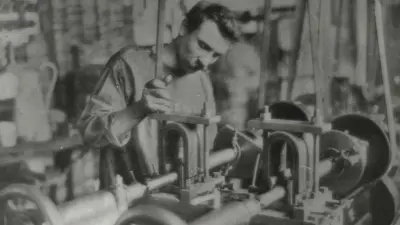

Machinery had found its way into factories during the first industrial revolution in the 19th century — long before Robert Bosch opened his workshop. The history of manufacturing at Bosch shows that both the company founder and his successors were keen to embrace cutting-edge production methods. To put it in modern terms, his “Workshop for Precision Mechanics and Electrical Engineering” was in effect a start-up riding the second major wave of industrialization. This second wave was one of factory electrification and more rationalized work processes. New and above all more robust materials also began to be used, and were soon in evidence in the first Bosch factories in downtown Stuttgart and in Feuerbach, on the outskirts of the city. Electrically driven drive belts snaked through the machine shops.

Mass production

By the 1920s, Bosch products no longer sold purely on the basis of good quality. The market was full of equivalent products selling for a lower price. This forced the company to streamline its own manufacturing operations. A production-line approach with more standardization and fewer variants reaped rewards, cutting the time taken to produce a magneto ignition system from fifty to five days.

During the three decades following the second world war, the third wave of industrialization saw computer-based methods become established at Bosch as well. For instance, numerically controlled machine tools started to take hold from the 1970s. And as a user and provider of industrial equipment, Bosch unveiled the first prototype of a swivel-arm industrial robot in 1976.

Growing importance of manufacturing management

Besides technological progress, manufacturing management also grew in importance. In the early 1970s, Bosch associates started exploring the kanban system, also known as the Toyota system. The aim was to structure the manufacturing process in such a way that any product at any stage of the supply chain was ready for immediate delivery to the next stage, thus minimizing inventory levels. During the 1980s and after, Bosch installed the key elements of kanban under the banner “controlled flexible manufacturing.”

Global competitive pressure persisted, and Japan remained a role model. This gave rise to new concepts at Bosch during the 1990s. The aim now was to make production lean, to steadily improve quality and processes, and to cut costs. And very importantly, it was hoped that the principle of continuous improvement would spark a change of attitude among associates.

Bosch Production System and Industry 4.0

The principle applies to this day, also under the Bosch Production System, which has overseen a reorganization of manufacturing since the turn of the millennium. It pursues the ambitious aims of zero-defect production together with 100-percent delivery fulfillment. This calls for a massive organizational effort, which is made considerably easier by digitalization and connectivity in the manufacturing process. The new buzzword is “Industry 4.0” – an allusion to the fourth wave of industrialization.

All the elements involved in production — machinery, logistics, and workpieces – use web-enabled sensors and software to communicate and collaborate. From the very start, Bosch has been actively involved in shaping the development of “smart factories” at various locations worldwide –as both a leading provider and a leading user.

Author: Christine Siegel