Gondola building in Venice — Tradition moving forwards

Roberto Tramontin builds gondolas in Venice, in a workshop that his great-grandfather founded over 130 years ago. He relies on time-tested family traditions — and innovative tools.

Tradition also has to keep developing

Roberto Tramontin has a passion for gondolas in his blood — just like his father, grandfather and great-grandfather. He is a fourth-generation gondola builder in Venice. His great-grandfather Domenico Tramontin opened his workshop in the district of Dorsoduro in 1884, two years before Robert Bosch founded his “Workshop for Precision Mechanics and Electrical Engineering” in Stuttgart.

While the latter has become a global company, the Tramontins have since become highly influential in constructing Venetian gondolas. Both success stories are based on the same mindset: “Tradition does not mean you always have to continue your old ways. You have to keep developing in order to improve,” says Roberto Tramontin.

-

Canal in Venice at sunset: traditional home of gondolas -

The Tramontins’ workshop: royal coat of arms over the entrance

“As time goes by, you recognize the value of this work and that you are doing something that is truly unique.”

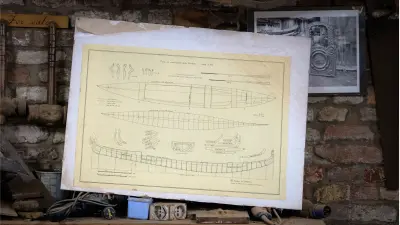

The way of thinking was responsible for an innovation pioneered by the Tramontins. They gave the gondola its asymmetrical shape — that means it glides in a straight line even though it is only rowed by the gondolier on the right: “I still use the same templates and shapes as my great-grandfather,” says Roberto Tramontin. Still hanging above the entrance to the workshop is the coat of arms of the Savoy royal family, recounting the family history of the Tramontins as an official supplier of one of the most important European dynasties.

Eight different woods

As a master gondola builder, Roberto Tramontin has an eye for wood: “One has to see the quality and choose it carefully. Hard oakwood for the sides, light spruce for the hull, cherry for the thwarts because it is easy to bend with fire. The inner frames are made out of elastic elm, and larch is used for the succhetto, the position of the gondolier at the stern. We still also use linden, walnut and mahogany.”

Before the sides are added to a gondola, the long planks have to be dried for months on end in the air and are then curved using fire and water — gondola building is a complicated process. “The quality of the tools we use to work the wood is therefore very important for us,” explains Tramontin.

280

parts that make up a gondola.

Old crafts, new tools

Traditional boatmaking tools include axes, saws, and planers. Roberto Tramontin still has his grandfather’s wooden planer which has been molded by being gripped in the hand over the years. “A planer needs to be lightweight because you mainly guide it one-handed, and work with it for a long time,” he explains. The same goes for the cordless planer from Bosch that Tramontin uses in for his daily craftsmanship. Easy-to-use, it gives him precision and flexibility in every position. Also the cordless edge router can be used one-handed thanks to the narrow and ergonomic shape — a tremendous improvement when working with convex or concave profiles.

“You put your soul and your body in every boat. You put all you have into it to make it even more perfect.”

Bosch’s power tools have passed the test at Venetian master boat builders and are advancing the traditional craftsmanship. “You see the wood lying there and you make something out of it that the world envies you for. It’s a symbol for Italy, not just for Venice. They even know what a gondola is in Himalaya,” says Roberto Tramontin. “I love building them. It comes from my heart, goes into my head, and then moves into the hands.”

Interview with Roberto Tramontin in his workshop

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.