Bosch in space

Ready for takeoff

Far-flung galaxies, zero gravity, and interplanetary voyages — humankind has been fascinated with space for centuries. Many projects are still only distant visions, but great strides have been made in our understanding of space since the 1960s. Bosch has been involved in many missions itself, both on earth and in the depths of space.

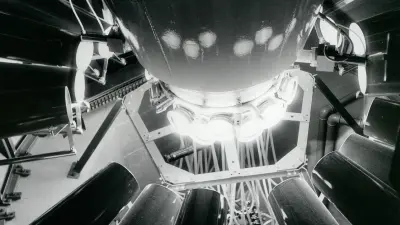

Simulation with the “Bosch sun”

The first man-made spacecraft did not have it easy. After surviving the rocket launch, they had to cope with the harsh conditions in space. Calculations set the basic tone, but they alone were not enough. Whether materials and designs would really function in space was something that could not be predicted — but it could be emulated. Simulation systems could generate the same vacuum found in space, along with ultra-low temperatures and high radiation from the sun.

In 1966, Bosch was tasked with building sun simulators for two space simulation chambers. The starting point was the company’s years of experience with bright arc lamps for cinema projectors, whose optical structure was similar to the projection systems for solar simulation. The engineering team in Stuttgart developed their first successful product, the “Bosch sun", which was used to put a whole range of European research satellites to the test.

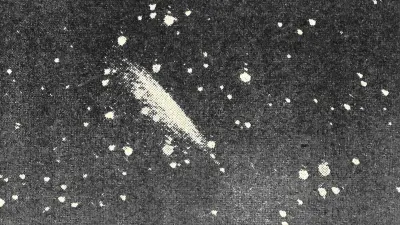

Stargazing through a TV camera

A second operating unit of Bosch, Fernseh GmbH (FESE), entered the vast reaches of space in 1969. At 74,000 kilometers up, an experiment was conducted to study interplanetary electromagnetic fields. After a small capsule containing barium copper oxide was ignited, the electrically charged barium particles followed the lines of magnetic force and formed a glowing red cloud of mist. To observe the barium cloud, which was similar to a comet’s tail, telescopes in Chile and Arizona were linked to specially developed TV cameras at FESE that “stacked” the weak light signals into an image and made it possible to analyze the experiment in the first place.

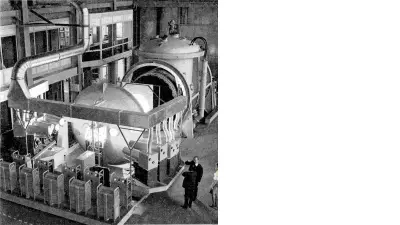

Pipes for Ariane

The Industrial Equipment division got involved in 1978, with the construction of the European launcher Ariane 1. Plans called for a ring-shaped tank holding 2,550 liters of water to cool the first rocket stage. The water tank was made up of 16 nickel-chromium steel half shells produced by the pipe construction team at the Reutlingen plant. The material had to meet extremely exacting requirements, withstanding extreme strain during takeoff while also adding as little as possible to the total weight. The report that appeared in Bosch-Zünder at the time was very confident: “When the first Ariane travels to space next year, then the quality of Bosch’s share in this project will also help to make this mission to space a success.”

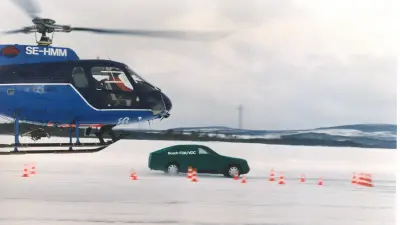

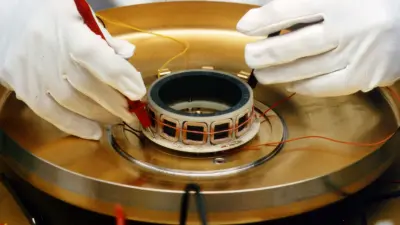

Flywheels for stable positioning

The 1980s brought the dawn of the golden age of space travel at Bosch. The acquisition of Teldix GmbH added space equipment to the company’s product portfolio. The reaction wheel system used to stabilize the position of satellites was a particular international success. A powerful, very fast-rotating gyroscopic wheel inside the satellites ensured that they could hold still in position. The directional antennas could then be aligned precisely to the relevant reception areas on the earth once the satellite was holding its position.

A telecommunications payload

The second big expansion of the space program came with the acquisition of a stake in ANT Nachrichtentechnik GmbH, based in the German town of Backnang. Since the late 1960s, the company had been developing numerous “telecommunications payloads” for satellites — meaning the satellites’ transmission systems for TV, radio, phone, telex, data, and other communication services. ANT also built terrestrial stations around the world to receive and process the satellite signals. One outstanding product was the traveling-wave tube amplifier, the “heart” of all satellites. It was responsible for amplifying the signals between satellites and ground stations to a sufficient degree.

Bosch’s first foray farther into space came in 1996. NASA’s Mars Global Surveyor began transmitting images and data in 1998 — amplified by traveling-wave tubes and a high-performance power supply from Bosch Telecom.

Mission to Mars

Bosch continued to be involved in various space exploration projects even after it exited the space and telecommunications segments. Some of these activities involved highly unusual uses of terrestrial products. In 2002, two Bosch spark plugs went along on a space shuttle mission, ensuring the supply of energy to a geophysics experiment.

On NASA’s Phoenix mission to Mars in 2007, a specialized drill from the subsidiary RotoZip played an important role in taking soil samples. An analysis of those samples ultimately confirmed researchers’ suspicions that the Martian soil contains frozen water.

In 2013, Bosch Rexroth also supported NASA by developing the hydraulics for a launchpad for a test project on options for “soft” landings on Mars.

Sensors in space

Bosch sensors have been in use in sensor systems on the International Space Station (ISS) since November 2019. SoundSee technology focuses on deep audio analytics and artificial intelligence. Microphones record the operating noises made by the space station, which are then analyzed using AI. The goal is for SoundSee to show whether the audio data generated by the ISS can be detected and interpreted correctly by software and used to improve the space station’s operations.

Another, even longer journey was made by the rate and acceleration sensors that landed on Mars with NASA’s Ingenuity helicopter in 2021. The small aircraft showed that controlled motorized flight is possible on Mars. The sensors stood up to the tough conditions on the Red Planet, joining the long series of different Bosch products that have proven themselves in space.

Author: Bettina Simon