Bosch diesel technology for the mass market

Distributor pumps for passenger cars as the key to success

Until half a century ago, diesel engines mainly featured in commercial vehicles. Only a few automakers opted for diesel engines in their cars. But then the distributor pump went into large-scale production. This new and cost-effective technology paved the way for diesel engines to become a common sight in passenger cars.

Slashing consumption by a quarter

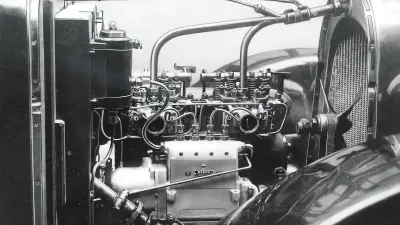

For the past decade or so, there has been a worldwide trend toward the electrification of passenger cars: electrically powered cars will displace combustion-engine models in the foreseeable future. Yet the combustion engine has a long history. In the case of diesel, it stretches back almost a century. It was late 1927 when Bosch first started volume production of diesel injection technology for commercial vehicles, thereby reducing fuel consumption by more than one-quarter. That same year saw the first experimental diesel passenger cars, and the first production diesel passenger car was presented to the public just under a decade later.

Diesel’s long wait for success in passenger cars

However, the first diesel-powered cars enjoyed only limited success. Critics bemoaned their excessive noise and their lack of power compared with their gasoline-powered cousins. But their low fuel consumption spoke in their favor, and this would repeatedly spark the automotive industry’s interest in diesel for passenger cars.

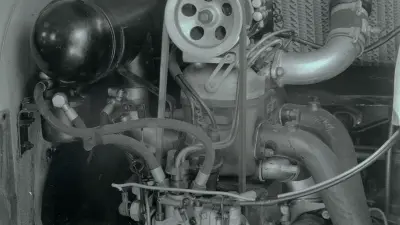

Until the 1970s, the idea that gasoline engines were for cars and diesel engines for trucks remained essentially unchallenged. Peugeot and Mercedes-Benz were the only manufacturers to offer a handful of diesel-powered passenger cars. Diesel also had a serious disadvantage, as a glance at the technical data highlights. Taking 35 seconds to accelerate from 0 to 100 kph, these cars sorely lacked punch. And there was another complicating factor: the robust and proven in-line pump technology sat firmly in the high-end price segment.

But half a century ago, diesel cars got a new boost. In 1976, having recently introduced its new VW Golf compact, the Volkswagen Group began accepting orders for a diesel-powered model. This move was also a reaction to the 1973 oil crisis, which laid bare the industrialized world’s dependence on oil exporters and underscored the urgent need to find ways of saving resources, especially in motorized transport. The start of production of the distributor pump at Bosch in 1975 was a timely response to this problem.

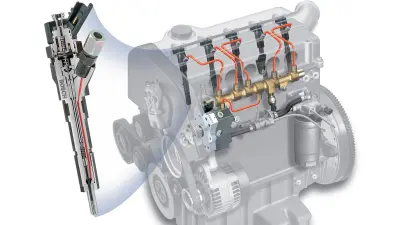

To make the technology affordable in the first place, Bosch had developed a completely new injection technology, based on a distributor pump instead of an in-line pump.

A new option: the distributor pump

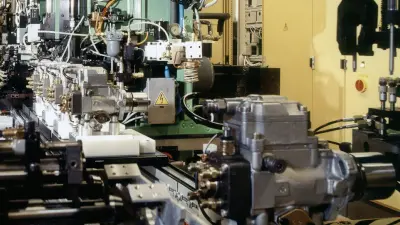

Development work on an inexpensive, lightweight pump that could be integrated into small engine compartments had already begun a good decade earlier. Bosch acquired the technical know-how for distributor injection pumps and started its first production run in 1962. However, producing the pumps was complex, their functional testing was time-consuming, and the design was extremely expensive to adapt to different numbers of cylinders. Moreover, their reliability failed to meet the exacting demands of diesel customers. Both the engine and the injection technology had to be robust, as they were often used in vehicles with very high annual mileage. At Bosch, this meant a long process of bringing the technology to maturity with a great deal of in-house engineering work.

Sales of diesel passenger cars running into the millions

But the basic principle was compelling and felt to be worth pursuing. In 1975, it was ready to go into large-scale production. The new pump, known internally at Bosch as “VE,” was ultimately the key to “democratizing” the diesel powertrain. This new technology finally brought down diesel powertrains’ historically high prices. It was no surprise that most European manufacturers followed Volkswagen’s lead and began offering diesel cars.

The figures illustrate this success: up to 1975, Bosch had been producing around 550,000 in-line pumps each year. Ten years later, the figure for distributor pumps was already a good 2.8 million. A diesel-powered vehicle was clearly suitable for buyers whose primary concern was low consumption rather than high performance and who could only afford a small or compact car. Clearly, they were prepared to overlook noise and comfort issues as minor inconveniences.

Perfection and new perspectives

To begin with, this development was primarily a European phenomenon. But with its economical 50 PS engine, the VW Golf also became an export hit. However, it would be another 20 years before diesel engines reached the performance level of gasoline engines, and before technology such as common rail made them much quieter and even more economical. As a result of these factors, diesel cars had achieved a market share of over 50 percent in some countries at around the turn of the millennium.

In Europe, the sales figures for diesel engines have now passed their peak, and diesel faces predatory competition from electric powertrains, not least because these have the potential to be practically emissions-free and thus more effective in mitigating climate change. But the two powertrain types have one thing in common: along both technology paths, Bosch has shown that it can develop the right concepts at the right time.

Author: Dietrich Kuhlgatz