Manufacturing technology at Bosch

From manual to mechanical

The evolution from the early years of building individual products by hand to today’s highly automated and connected approach to manufacturing constitutes a giant leap forward. Robert Bosch recognized at an early stage in the game that innovative manufacturing technology was the key to remaining competitive. As a result, the continuous improvement and linking of processes, machines, and equipment have long been part of the very fabric of the company.

A small automated guided vehicle (AGV) approaches a machine workstation to deliver parts for assembly. It rolls on to the next station, all while neatly avoiding a collision with a human colleague. The AGV stops and provides an associate and the collaborative robot right next to her with material. With all of the machines on the shop floor connected to each other wirelessly, the manufacturing unit was able to order the new supplies itself. All production and logistics data is available in real time. Thanks to flexible and compatible control software, adapting and adjusting products and processes in no time flat is a piece of cake.

Science fiction? No, a glance inside the Bosch lead plant for Industry 4.0 in Stuttgart-Feuerbach. Since November 2020, production has been underway using the company’s first 5G campus network. This local cellular network, which has been adapted to the demands of industrial communication, is another important component of Industry 4.0 that makes managing the entire manufacturing network in a more targeted manner even easier than before. In production, it fulfills key criteria by being economical, sustainable, technically flexible, and connected.

With caution and conviction

A little over 130 year ago, things looked a bit different at Robert Bosch’s Workshop for Precision Mechanics and Electrical Engineering. He and his associates experienced the ups and downs of everyday life at a small workshop for skilled trades. Bosch assigned his technicians and fitters their tasks at the start of the working day. The work was very diverse, with associates switching from simple precision-mechanical repairs in the workshop to complex electrical installations on site. If rush orders came in, it was not unknown for the boss to call associates working at a customer’s place of business back to the workshop – with colleagues sometimes having to return by express train. Robert Bosch even lent a hand nailing crates to ensure that the goods would be delivered on time.

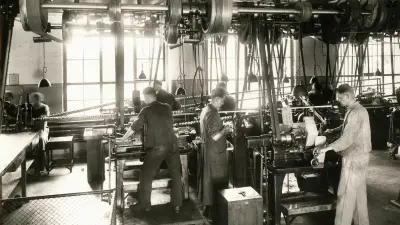

From the very start, Robert Bosch placed great value on making sure his workshop was well equipped with machines and tools. He was a firm believer that proper equipment was essential to manufacturing high-quality products. The reliability and quality of the company’s first major success, the magneto ignition device for automobiles, would prove him right. The master craftsmen at the company made sure that special machines and equipment were built as needed in order to make production processes simpler, faster, and more efficient.

-

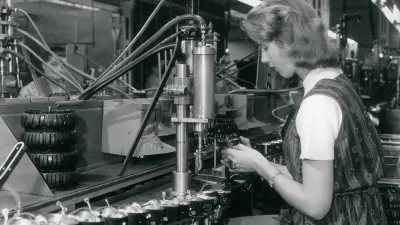

After the changeover to assembly-line work: bicycle lamp production in Stuttgart, 1925 -

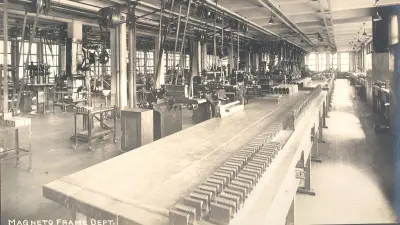

Ready to start production: manufacturing department at the new factory in Springfield, MA, USA, 1911

The early years of industrial technology at Bosch

As a result, industrial technology made its first inroads into the company’s portfolio in the years just after 1900. While most technicians still preferred to make products one at a time, the sharp rise in demand for magneto ignition systems made it difficult to manufacture large volumes of the devices using the customary methods. In 1922, plant manager Alfred Häcker had this to say about the production process: “The principle of dividing up labor and performing the individual stages of the manufacturing process on special machines is commonplace at our plants as well.”

The crisis in the car industry in the mid-1920s further intensified the need for an economical and rational approach to production. Bosch director Max Rall, who went to the United States to study the methods used there, was both fascinated and alarmed by the assembly-line production techniques in place at Ford, where staff worked at “breakneck speed …, throwing together 8,000 generators and 8,000 starters a day.”

In order to be successful in the international market, Bosch switched to assembly-line production, allowing it to save the necessary amount of time and money.

Rationalization and automation

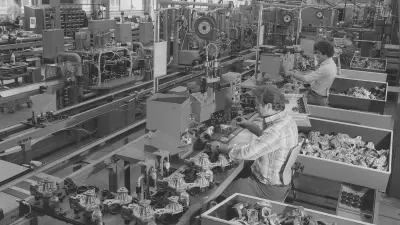

The use of new, continuously improved machines and tailored work processes made it possible to consistently rationalize production. Industrial technology received a major boost as a result of the advancements in microelectronics from the late 1960s onward. Electronic control technology initially helped optimize large-scale production and brought industrial robots to the shop floor to perform tasks such as welding and coating. While robots were capable of providing support for arduous, repetitive tasks, it was their integration into the overall assembly and handling system that would prove decisive.

Production by hand would continue to dominate for some time to come, especially for the assembly of small and medium-sized production runs. But the times were changing. Product cycles grew shorter, reducing batch sizes altogether. High inventory levels became a cost risk, as did fluctuations in the utilization of production equipment. With 20 to 50 percent of a product’s manufacturing costs attributable to assembly, minimizing assembly costs was essential to securing the competitiveness of the company.

In 1980, Bosch unveiled its modular flexible assembly system. The program’s modules offered customers the greatest possible flexibility and covered the entire spectrum of assembly-related tasks. The modules could be combined with each other as needed, with transfer systems transporting workpieces over a network of conveyor belts and supply technology applications bringing missing parts to the assembly line. Ergonomically designed manual workstations were as much a part of the approach as programmable monoaxial and multiaxial robot units from the world of handling systems. Other hardware included standardized racks, workbenches, and other components, as well as electrical equipment and software solutions to manage the entire process and support customers along their journey from planning to operation.

Connected manufacturing technology

As a full-package solution, the flexible assembly system earned itself a place at many factories worldwide. Its adaptation to the variety of tasks involved with customer projects and production activities within Bosch contributed to the constant development and enhancement of the hardware and software modules. Early on, it became apparent that sharing and communication among the projects, people, and machines involved would be the decisive next step in the manufacturing technology development process. In 2011, the concept of an intelligent, connected factory led to the creation of the official term “Industry 4.0.” Since then, a lot has changed at Bosch. The APAS collaborative robot, for example, can work together with humans in production without the need for an additional safety enclosure. While the Active Shuttle transport system maintains the flow of materials, innovative software platforms such as Nexeed and ctrlX AUTOMATION are making processes even more integrative and flexible. To put it simply, Bosch’s factories are ready for the future of manufacturing.

Author: Bettina Simon