Revolutionizing hydrogen filling stations with compressor technology

Hydrogen pioneer on Switzerland’s roads: a tour with the Coop truck driver Jean-Marie Walter

In today’s world, sustainability is becoming increasingly important, also when selecting products from food shelves. But such considerations start much earlier, and are not only a matter of the food we put in our shopping carts. When developing and making these products, as well as when distributing them, sustainability already plays an important part. In road freight, sustainably produced hydrogen can help deliver goods in a more climate-friendly way. Fuel-cell vehicles are above all a good choice for long hauls and heavy loads. But they also need the right framework conditions — a network of hydrogen filling stations is a must.

A hydrogen pioneer plying the roads of Switzerland

A look across the Swiss border provides insights into the world of hydrogen mobility, and shows how awareness of sustainability and environmental protection is growing. Take Jean-Marie Walter. He is an experienced driver at Coop — and also a pioneer. His hydrogen truck is a good illustration of the connection between innovation and climate action, especially in the transportation sector. Road freight is currently responsible for just under 30 percent of Switzerland’s carbon emissions. Carbon-free fuels such as hydrogen can play a part in decarbonizing the transportation sector. After all, electrifying long-haul freight with heavy payloads is very difficult.

It’s early morning at the logistics center in Schafisheim when Jean-Marie’s shift starts. He carefully loads food products onto his truck. After thousands of tours for Coop, he knows exactly what to do. “I’ve been driving this hydrogen truck for more than three years, and I love using it for my tours. One tank full is enough for 340 kilometers in winter, and for as much as 400 kilometers in the summer. For the tours I have to make in Switzerland, this range is more than enough,” Jean-Marie says, while he stows the goods in his truck.

Hydrogen technology in action

Driving through the Swiss countryside, Jean-Marie explains the technology behind his hydrogen truck and the benefits of this powertrain system. He explains that a fuel cell helps convert gaseous hydrogen into electricity, which then drives the electric motor. All the truck emits locally is environmentally friendly steam. He is especially keen to point out one thing: “Hydrogen trucks are very quiet. There’s no loud engine noise. And there’s more thrust when driving off. Acceleration is much better than with conventional combustion engines.”

For people like Jean-Marie whose job involves a lot of driving, an extensive hydrogen filling station infrastructure is key. With its 17 hydrogen filling stations, Switzerland is among the frontrunners here. In fact, it ranks fourth in Europe. Jean-Marie can see this for himself. Today’s tour will take him past three hydrogen filling stations. “I can simply choose the one that suits me best.”

Before a good hydrogen filling station network can be set up, a number of challenges have to be solved. Apart from choosing the right location, official support is just as important as collaboration with the right technology partners — partners who can help with project planning.

7 hydrogen trucks

are already on the road for Coop. Jean-Marie drives one of them.

Loading the video requires your consent. If you agree by clicking on the Play icon, the video will load and data will be transmitted to Google as well as information will be accessed and stored by Google on your device. Google may be able to link these data or information with existing data.

Next stop: the future!

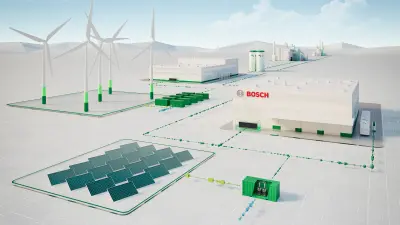

Jean-Marie’s tour takes him to the hydrogen filling station in Frenkendorf. It’s the first such station in northwest Switzerland, and has been in operation since 2021. Roger Hausammann supervised its construction. “Our aim is to encourage hydrogen mobility in Switzerland and to play our part in making the future emissions-free and convenient. Coop was quick to opt for hydrogen. In 2016, we opened the first public hydrogen filling station in Switzerland. Today, Coop Mineraloel AG operates 6 of Switzerland’s 17 hydrogen filling stations. And it operates five of them with our partners Maximator Hydrogen and Bosch Rexroth. The last of them was only just opened, in February 2024.”

This makes Coop the market leader, currently responsible for roughly one-third of Switzerland’s hydrogen filling station network. Technology plays a pivotal role here. In the case of Coop, it comes from Maximator Hydrogen and Bosch Rexroth. “Thanks to a highly efficient compressor and automatic seal exchange, we can minimize both idle times and operating and maintenance costs,” Hausammann says. As a rule, a seal can be replaced within ten minutes. “This means we can be online again faster, as maintenance work only very briefly puts the filling stations out of action.” Without this innovation, he adds, such a procedure usually takes up to three days.

The core element of the state-of-the-art hydrogen filling station in Frenkendorf is a Maximator Hydrogen compressor unit featuring Bosch Rexroth drive technology. Development of this innovative technology started in 2017. It allows the hydrogen needed for fuel cells to be filled directly from the storage tank, without any need for intermediate storage. As hydrogen is usually stored in a gaseous state, it first has to be highly compressed to a pressure of 900 bar. It is only as a result of this compression that vehicles can refuel rapidly and smoothly with hydrogen.

Time for innovation

While Jean-Marie starts the hydrogen refueling process, he talks about his experiences as a hydrogen truck driver. “Compared with conventional refueling, the process takes a little longer: roughly 15 to 20 minutes if the tank is empty. So that gives you enough time for a coffee break.” For drivers, who often have to stick to strict schedules, it is easy to plan for such short breaks. It’s also a chance for a pleasant breather.

700 tons of hydrogen

are filled into vehicles each year on average. This makes Switzerland number one in Europe.

Adieu, Jean-Marie

After making his goodbyes, Jean-Marie climbs back into his hydrogen truck and sets off for his final delivery stop. He is proud to work for a company that took on the job of expanding the hydrogen filling station network at such an early stage. Its initiative is now benefiting from the pioneering technologies of Maximator Hydrogen and Bosch Rexroth. With their innovative compressor and drive technologies, the two companies are putting their faith in sustainable mobility. “Especially now I’m a grandfather, I feel it’s important to create a future fit for the generations to come!”

Partnership for a sustainable future:

Mathias Kurras and Helmut Kern are driving the hydrogen revolution forward

Maximator Hydrogen and Bosch Rexroth aren’t just about solutions for compressing hydrogen for filling stations, but also about close partnership. Mathias Kurras, the CEO of Maximator Hydrogen, stresses the long-standing collaboration with Bosch Rexroth. He says: “For a decade now, we have been working together to equip filling stations for Coop. We set the highest technological standards and share a passion for eco-friendly solutions.” They intend to stay on this path in the future as well. Their common goal for 2030 is to have supplied 4,000 compressor units for hydrogen filling stations worldwide, and in this way to further expand hydrogen infrastructure. “This partnership with Bosch Rexroth brings the very best experts together,” Mathias Kurras says.

Helmut Kern, who works in sales and project management at Bosch Rexroth, has 40 years of experience in the industrial applications department, where he is responsible for managing projects and selling hydraulic systems. He believes that hydrogen is the ideal fuel. He also underscores the direct collaboration with Maximator Hydrogen: “We are a globally leading supplier of drive and control technologies. For the energy-efficient operation of the hydrogen compressor, we supply Maximator Hydrogen with a scalable systems solution. In this process, we are in constant close contact. Our long-standing collaboration shows how enormously important innovativeness and technology partners are in our industry.”