Seamless operations

A research network has digitized supply chain management

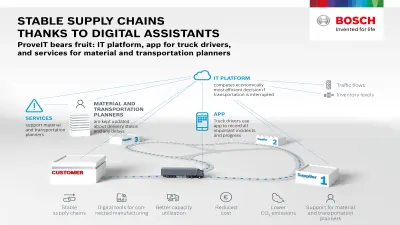

Efficient truck transport is part planning and part luck: after all, congestion, stop-and-go traffic, and delays during the loading process cannot be predicted. However, the ProveIT platform attempts to mitigate the impact of the unexpected with advance planning and deviation management when emergency strikes.

A journey into the unknown

Homburg, Bexbacher Straße 72, 7:30 a.m. A truck drives off the Bosch site. It will travel to suppliers within a sixty-kilometer radius and collect the goods the company needs to produce hydraulic components. When all goes as planned, the trip contributes to the seamless operation of the entire logistics network. Sometimes, however, things go wrong: the truck gets stuck in traffic, or the loading process is delayed.

When this happens, material and transport planners must adjust. While they have to make sure that the goods are available on time and ready for production in Homburg, they recently began receiving extra support. Thanks to the ProveIT research project, which aimed to optimize connected supply chains, logistics providers can now monitor a plant’s entire supply chain and respond even more efficiently when something goes wrong.

“Production plan based recovery of vehicle routing plans within integrated transport networks”...

Prepared for anything

Before the trucks set off, ProveIT recommends the ideal route to material and transport planners. In so doing, the platform aims to make the best possible use of all transport channels, thus enabling companies to improve their transport performance, cut costs, and reduce CO₂ emissions.

Help in dealing with delays...

The truck driver also has access to the platform, and can provide status updates via an app. This includes information about departures, arrivals, the beginning and end of loading processes, departures from a stop on a truck’s route, and disturbances along the way. For instance, when a truck is stuck in traffic, the integrated deviation management tool calculates the most efficient solution. This may mean that the truck will continue its route despite the delay, or that a second truck will make its way to a supplier whose goods are most urgently needed for production. “The logistics provider can rely on the digital helper to monitor the trip. A warning is issued only when physical intervention is required,” says Dr. Markus Bauer, program manager for logistics IT at Bosch and head of the research project.

Still a way to go

The IT platform, the app for truck drivers, and other services for logistics providers testify to the success of the three-year ProveIT research project. Bosch headed the project, which was carried out in cooperation with seven companies and institutes: the industrial company ZF, the software development companies PTV and LOCOM, the logistics company Geis, the Institute for Material Handling and Logistics Systems (IFL) of the Karlsruhe Institute for Technology, and the Informatics Research Center (FZI). The project was funded by the German Federal Ministry of the Economy and Energy.

Once the project was completed, Bosch entered a cooperation with FZI. Among other things, both partners intend to develop additional application functions such as digital freight documents with the aim of adding them to Bosch transport processes.

Summary

Complex supply chains pose a major challenge for logistics providers. With the completion of the ProveIT research project, which was headed by Bosch, logistics providers can now master this challenge, as digital helpers now handle most of the difficult decisions that transport and material managers were once responsible for.