Nexeed — welcome to the smart factory

The better connected the production and logistics processes, the more efficient and resource-friendly industrial manufacturing will be — that, in a nutshell, is the key that unlocks the door to the factory of the future. And Bosch has smart software to connect all the diverse data streams.

Where efficiency and precision save lives

The products that roll off the production line at the Bosch plant in Blaichach help keep roads safe around the world. At this plant in the Oberallgäu region of southern Germany, Bosch manufactures automotive technology such as ABS and ESP. It is up to Christoph Kunz and his coworkers to keep production running smoothly and ensure the components satisfy the highest quality standards. Smart software called Nexeed helps them get the job done.

Knowing what 60,000 sensors see

An industry 4.0 software suite developed by Bosch Connected Industry reads out data from more than 60,000 sensors and delivers the relevant information to Kunz in real time. This makes predictive maintenance possible. For example, the data can indicate that a caulking tool on the assembly line will soon need to be serviced. This anticipatory response minimizes machine downtime. The Blaichach plant alone has reduced disruptions in its ESP manufacturing operations by a quarter.

Kunz can keep track of individual machines’ condition on his desktop computer, or on his tablet when he is on the move. He can even monitor all the manufacturing operations in one machine shop. These are just some of the ways in which smart software systems like Nexeed take us one step closer to the factory of the future.

Nexeed in manufacturing — all the benefits of the IoT for both new and existing machinery

One core component of this software suite is the Industrial Application System. It interfaces with all connected manufacturing industry applications via a single uniform dashboard and user interface. This kind of connectivity requires painstaking programming — both to handle data sourced from so many machines and systems along the value chain, and to interpret the many formats and communication protocols across the supply chain. A digital twin — that is, a digital representation of physical assets such as machinery — collects and homogenizes this data. This uniform data is then easier to process, analyze, and share. Everyone wins — the companies that build the machines, the people who develop the software, and the engineers who operate and maintain the production lines. A simple example illustrates how this works. Let’s say a machine sends the following combination of numbers: 1 + 2019-09-25T08:15 + 23.8.

A digital twin then interprets this to generate an alert that reads something like this: “The coolant temperature at 8:15 a.m. on November 25, 2019, was 23.8°C, 3.8 degrees above the standard operating temperature of 20°C.” Nexeed has another great advantage: as an open system, it is easy to retrofit on legacy production lines. The retrofit serves to connect machines to the internet of things (IoT), or more accurately the industrial IoT (IIoT). All in all, the Nexeed Industrial Application System comprises 16 specialized applications and several standalone solutions. Bosch Connected Industry also provides technical support, offers further training, and helps companies get the system up and running.

“Nexeed is the brains of our production facility. It makes processes transparent and tells our machinery what to do and when to do it.”

A look at the factory of the future

In the smart factory of the future, it will be easy to reconfigure machinery and to scale up or scale down production lines according to requirements. Power will be supplied by induction loops embedded in the factory floor, instead of by cable. Automated guided vehicles delivering parts, humans working at close quarters with robots, ultrafast 5G networks sharing data in real time — Nexeed is helping pave the way to all this and more. Today, it is already capable of assigning any order to the right machinery.

It automatically programs the designated production line with the required data, which then processes each job order accordingly. The production data this generates is presented clearly and is accessible at all times, which means that manufacturing operations can be precisely evaluated and improved. The statistics back this up: individual Bosch locations have boosted productivity by up to 25 percent and reduced inventories by as much as 30 percent.

Nexeed in logistics — the ticket to total transparency

Nexeed also facilitates logistics. An app called Nexeed Intralogistics Execution maps materials flows to provide a completely transparent view of their movements from warehouse to production-line workstation. Serving as a control center, it enables plant supervisors to steer all transport job orders throughout the plant. Other vendor’s transport systems can also be integrated. This software provides real-time information on where materials are headed, the status of the vehicle fleet, and transport routes. The Bosch location in Homburg, Germany, used Nexeed to optimize its entire intralogistics system.

It now takes only half as long to collect information on materials flow and status. The milk runs that keep workstations on the shop floor supplied with components are now up to 35 percent more efficient. The drivers of milk-run vehicles have tablets to guide them and Nexeed to map out the most efficient delivery route on the fly. In the past, milk-run routes were fixed. A vehicle would stop at every location on the tour, irrespective of whether drop-off points needed new materials or not.

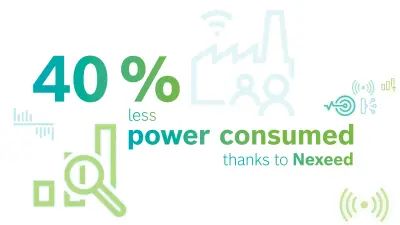

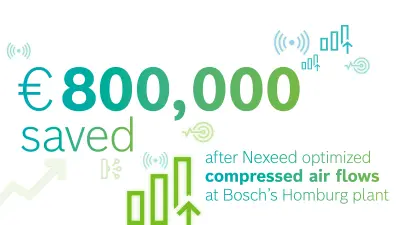

Nexeed in energy management — digitalization to cut waste

Above all, efficiency is a synonym for sustainability. Digitalized energy management can help shrink a plant’s carbon footprint. Based on the solid foundation of Bosch Building Technologies’ know-how, the Nexeed Energy Platform is the launch platform for such initiatives. The Homburg plant is a case in point — it consumes 40 percent less power thanks to Nexeed. Among other things, it achieved this by optimizing its compressed air system. More than 90 percent of its machinery runs on compressed air, and generating this air accounts for 15 to 20 percent of the power consumed on the shop floor. Unlike lubricant or fuel leaks, minor leaks of compressed air are not critical, and will not stop a machine from working. However, the machine will consume a lot more air. And even when a leaky machine has been shut down for repair, around half of all leaks remain undetected. The Homburg plant went about this a different way, using Nexeed to combine readings taken from meters and sensors. On the basis of this information, the software was able to pinpoint leaks. This has saved the location 800,000 euros a year, and the payback period for the capital outlay was less than two years.

In use at Bosch and other companies

Many Bosch plants’ manufacturing systems and logistics processes have been optimized with Industry 4.0 solutions. More than half use Nexeed. Over 100 Bosch customers worldwide are now benefiting from the company’s expertise as it spearheads the transition to the smart factory.

The experts at Bosch Connected Industry drew on a deep well of experience and partnered with associates at Bosch plants to develop Nexeed. Now Bosch Connected Industry locations in Germany, Hungary, and China are working on further Industry 4.0 applications to control and connect manufacturing and logistics.