Quigo Green: five steps toward the creation of a more sustainable product

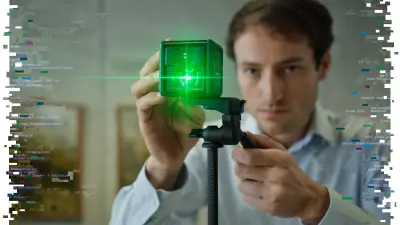

Green cross-line laser for creative DIY projects

Quigo Green, a new green cross-line laser, marks a milestone in the development of more sustainable power tools from Bosch. As such, it is destined to provide a model for the creation of further products of this type. But what exactly does this kind of development process entail? We asked two central figures at Bosch Power Tools: Isabelle Gola, head of sustainability strategy, and Simon Kalt, sustainability coordinator and expert in measuring technology. Drawing on the example of the Quigo Green, they name five crucial steps toward making a product more sustainable.

#1 — Our vision: the first power tool to be designed more sustainability from square one

Sustainability is a crucial plank of product strategy at Bosch Power Tools. Together with their teams, Isabelle and Simon are systematically working to achieve greater sustainability along the entire value chain. In the process, they aim to achieve a long-term reduction in the tools’ carbon footprint and encourage circular business models. All in all, Bosch Power Tools is looking to achieve a 15 percent reduction in so-called scope 3 carbon emissions by 2030. This includes the indirect release of greenhouse gases both upstream and downstream of the company’s actual activities – in the supply chain, for example, or during product use.

The new Quigo Green is the first ever power tool from Bosch to have a significantly reduced carbon footprint all the way from the product itself to its accessories and packaging. On a technical level, too, the Quigo Green is an outstanding piece of technology. The self-leveling laser projects a vertical and horizontal green line onto the wall to form a perfectly aligned laser cross. This replaces a conventional spirit level, thereby freeing the user to work with both hands. Moreover, the lines from the green laser diode are up to four times more visible than red laser lines and extend the working area to as much as 12 meters. It’s therefore suitable for a wide range of jobs, offering a quick and easy route to hanging pictures, tiling walls, or fixing curtain rails — all perfectly aligned and without the need for a second pair of hands.

#2 — Life cycle analysis: identifying carbon hot spots

Increasingly, at the outset of product development, Bosch Power Tools conducts a systematic analysis of each phase of the life cycle — from production of the raw materials, through manufacture of the product, to its distribution, use, and ultimate disposal. The aim is to pinpoint all the potential environmental impacts resulting either directly or indirectly from a proposed product or service. Once these carbon hot spots have been identified, the development team can then look into potential mitigations with which to reduce emissions. If the analysis reveals that certain types of plastic have an increased environmental impact, the quest begins to reduce their use or replace them entirely with a recycled polymer.

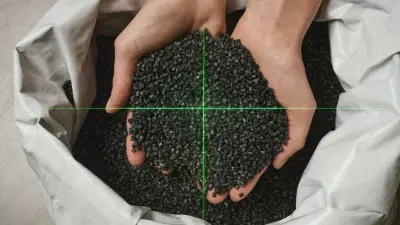

#3 — Recycled plastics: a new resource

Given the increasing scarcity of resources — and the growing burden of waste — Bosch is now aiming to use only recyclable materials in its manufacturing operations. In other words, the raw materials can be processed, used, recycled, and then reused. This is the principle behind a sustainable and climate-neutral use of plastics. In the case of Quigo Green, the majority of plastic components are now manufactured from recycled materials. The product housing, for example, comprises 85 percent recycled plastic, and the MM 2 universal clamp and adapter plate, which are supplied as accessories, together comprise 95 percent recycled plastic.

#4 — Packaging: where less means more!

Packaging is an essential aspect of any sustainability strategy. Bosch therefore intends to increase the proportion of recycled materials in a whole variety of packaging and to ensure that the packaging materials themselves are recyclable. At the same time, improvements in both the size and design of packaging will help reduce waste and thereby conserve natural resources. In the case of the new Quigo Green, the team has adjusted packaging size dimensions so that the product has ideal dimensions for stacking on a pallet. This increases the number of units per pallet by ten percent — a significant logistics gain in terms of both efficiency and environmental impact. The new packaging materials for the Quigo Green are plastic-free and comprise at least 70 percent recycled paper, and the operating instructions and product brochures are made of 100 percent recycled paper. The box itself is coated with an environmentally friendly, water-based coating and no longer contains any plastic film within. Bosch will therefore eliminate the use of around 172,000 plastic bags as well as 50,000 plastic battery film wraps during production of the Quigo Green in 2022.

#5 — Enhanced electronics

Thanks to significantly enhanced electronics, the new Quigo Green is even more eco-friendly, requiring 50 percent less energy than its predecessor. As a result, battery life increases from two to three hours. In turn, longer battery life means that it requires fewer batteries during its service life, thereby conserving resources and reducing waste. Building on this strategy of sustainable product development, Bosch now intends to apply it to other product families and their packaging and to broaden the collaborative scope of its sustainability projects.